Welcome to FireCAD

FireCAD: The Premier Solution for Thermal Design of Industrial Boilers

FireCAD stands as the global leader in thermal design software for industrial boilers. Our platform is trusted by boiler manufacturers, engineers, consultants, and academicians for the design of a wide variety of industrial boilers.

Whether you require solutions for water tube or fire tube boilers, or for systems fueled by coal, biomass, or gas/oil, FireCAD provides comprehensive tools to ensure precise thermal design and performance calculations.

Our software supports the design of Grate-fired boilers, Water tube package boilers, Fire tube boilers (both fired and waste heat types), combi boilers, FBC boilers, Heat Recovery Boilers, economizers, air heaters, and superheaters. Additionally, we offer expert consultancy services for various industrial boiler applications, including oil-fired, gas, wood, hot water, and combi boilers, ensuring tailored solutions that meet your specific needs.

FireCAD Boiler Design Software

- Grate Fired Boiler – 3 tph to 250 tph of steam

- Fire Tube Boiler – 200 kg/hr to 50 tph

- Water Tube Pkg Boiler – 3 tph to 150 tph

- Economizer software – up to 1000 tph

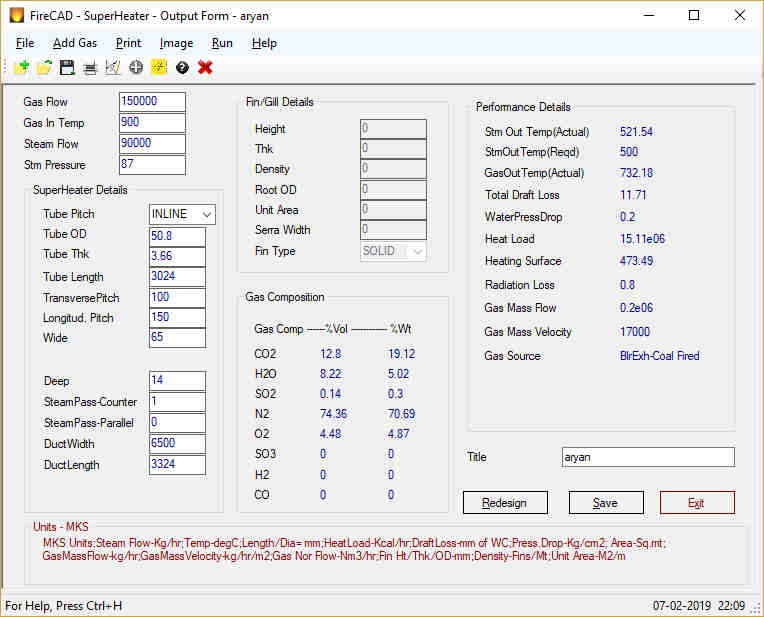

- Superheater software

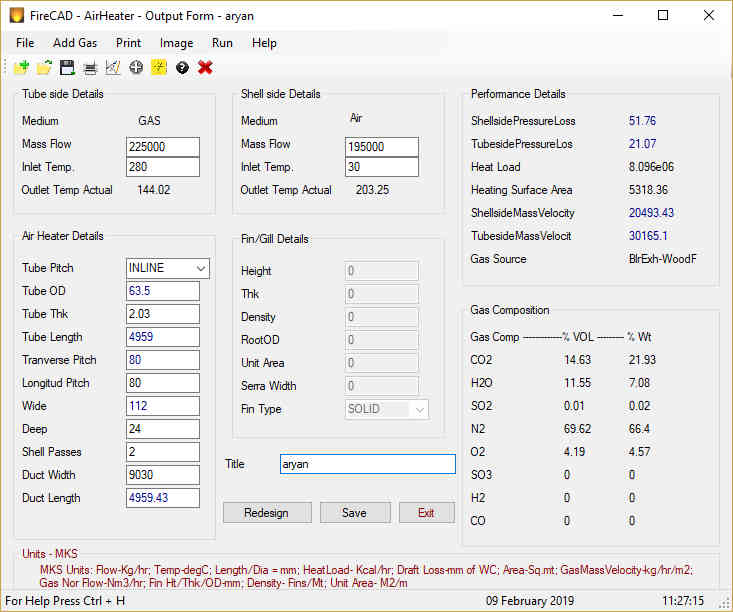

- Airheater software

Steam, Water and Exhaust Gas properties like Conductivity, Dynamic Viscosity, Kinematic Viscosity, Density and Specific Heat are calculated at a given temperature.

- Fuel Combustion : Calculations to find out exhaust gas composition, gross and net calorific values (Higher heating value and Lower heating value), unit air and unit gas quantities.

- Boiler Efficiency: Online calculator does combustion and boiler efficiency calculations to determine Gross and net efficiencies.

- Flash Steam: Calculates quantity of flash steam from blowdown tank.

Upcoming..

Shell Thickness

Thickness Flat unstayed heads, covers, or blind flanges

Thickness of Dished Head

Thk of Dished Head(full Hemispherical)

Stand Pipes/Nozzles/Headers Thickness

Max Allowable Press of Tubes

Boiler Tube Thickness

Boiler Header Thickness

Max Allowable Pressure of Piping

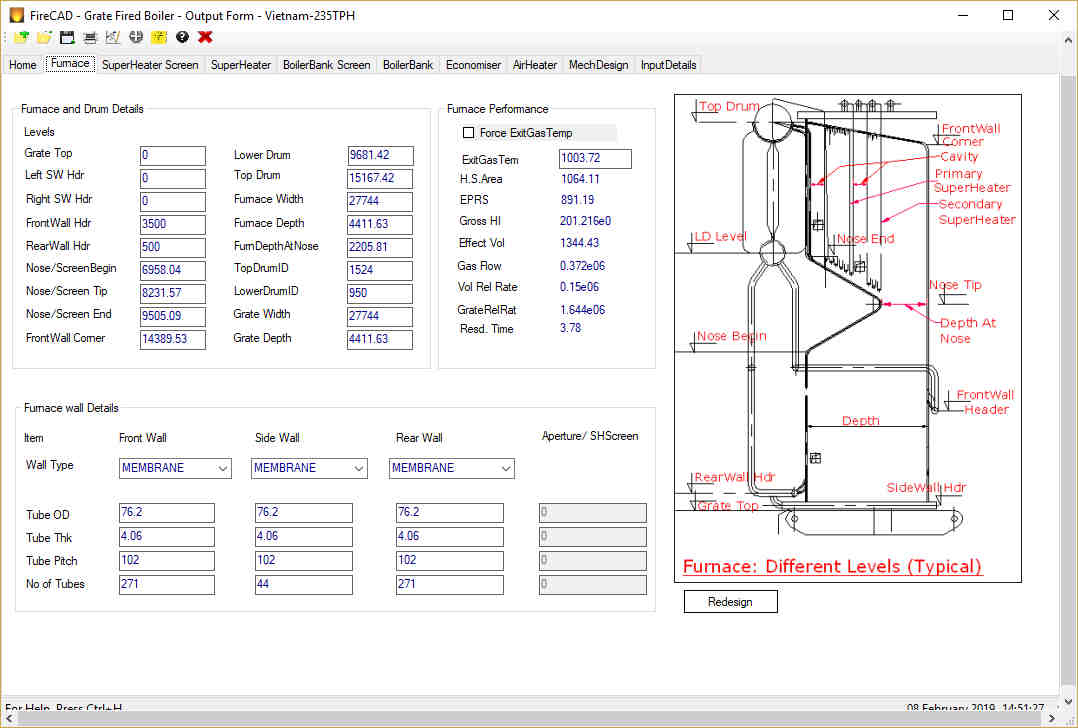

Solid fuel fired Steam Generators up to 250,000 Kg/hr and 550 degC can be designed.

Solid fuel fired Steam Generators up to 250,000 Kg/hr and 550 degC can be designed.- Fuels : Coal, Lignite, bagasse, Rice husk, wood ,other Bio-mass boilers

- Grates : Dumping Grate, Travelling Grate, Stationery and Water Cooled Grates

- Furnace : Membrane tubes, Tangent Tubes, Space Tubes or Refractory wall

- SuperHeater : Single Stage and Two stage. Counter and Parallel flow type with or without protective screen.

- Boiler Bank: Water Tube or Fire Tube boiler Bank. Combination Boilers or Combi boilers with water tube furnace and Fire Tube Boiler bank.

- Water Tube boiler Bank : Cross Flow or Long Flow type.

- Fire Tube Boiler : Single Pass or Two Pass.

- Economizer: Single pass or Multi pass with Bare/Fin/Gill tubes.

- Air Heater: Single or Multi Pass.

- Units : SI/MKS/FPS available

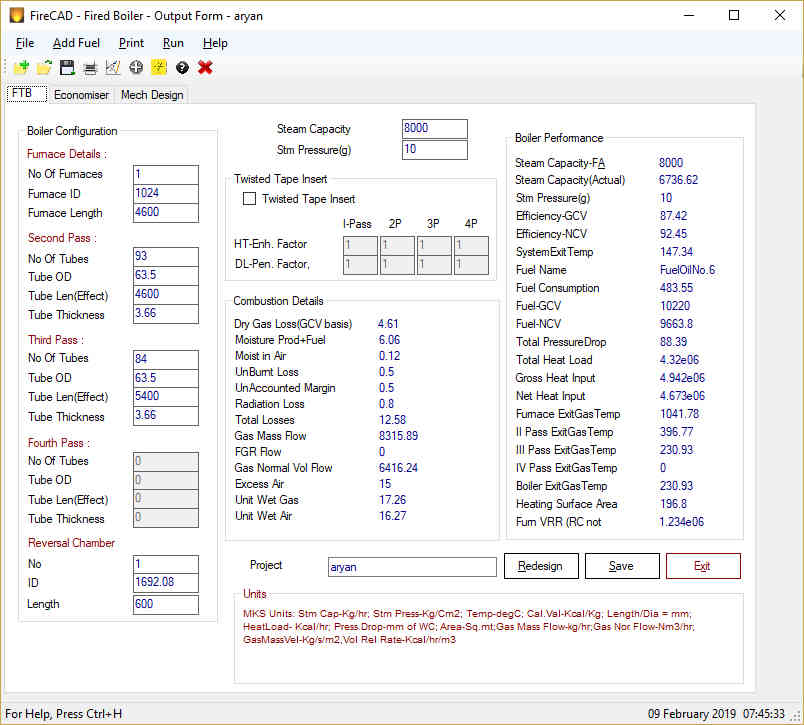

Useful for designing Fire Tube Package Boilers and Waste heat boilers of any range and pressure

Useful for designing Fire Tube Package Boilers and Waste heat boilers of any range and pressure- Oil fired boilers,gas fired boilers and coal other solid fuel fired boilers can be designed

- Novice as well as expert design engineers for quick and accurate designs.

- Extensive Fuel and Waste gases database.

- Wet back or Dry back and 2,3,4 pass Boilers can be designed.

- Waste heat boilers(Fire Tube) for Chemical/DG set/Process/Metallurgical/Power plants can be designed.

- Fired/Unfired Hot Water Generators can be designed.

- Option to include Economiser with Bare/Fin/Gill tubes.

- MKS/SI/FPS units supported

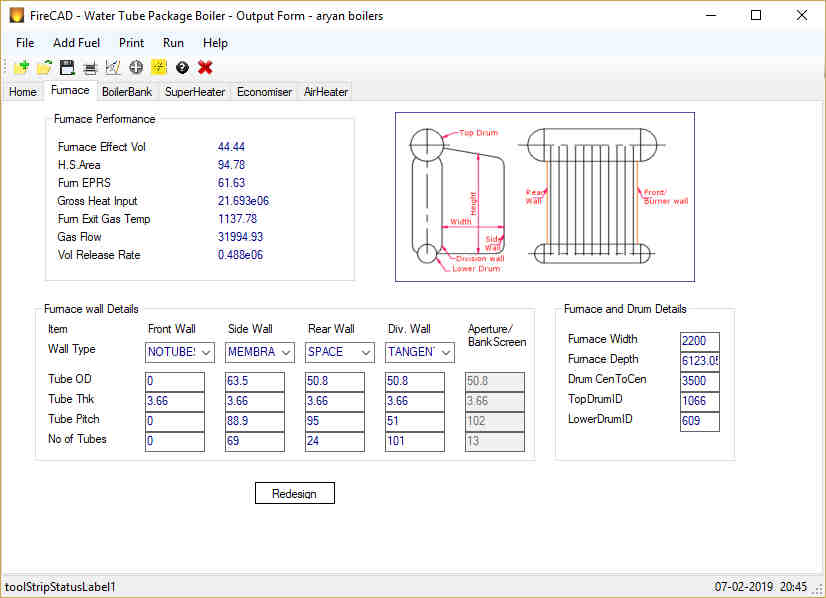

Water Tube Package Boilers up to 150,000 Kg/hr and 170 Kg/cm2 pressure can designed

Water Tube Package Boilers up to 150,000 Kg/hr and 170 Kg/cm2 pressure can designed- Oil as well as Gas fired Boilers can be designed.

- Novice as well as expert design engineers for quick and accurate designs.

- Extensive Fuel database.

- D-type package boilers

- Option to include Economizer and Air-heater with Bare/Fin/Gill tubes.

- MKS/SI/FPS units supported

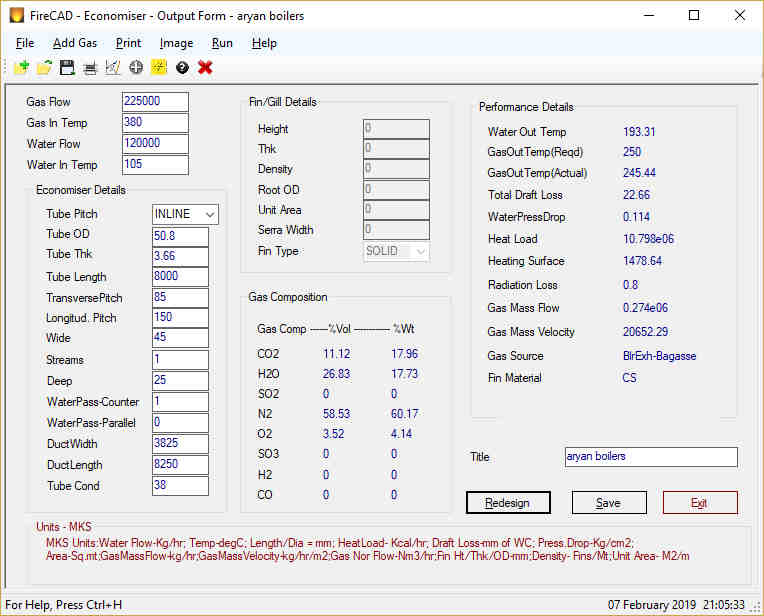

Design a wide variety of Economisers for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.

Design a wide variety of Economisers for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.- Large database of Waste heat gases and Boiler Exhaust gases is provided.

- All types of Bare tube, Fin tube and Gill tube Economisers can be designed.

- Bare tube, Fin tube and Gill tube Economisers can be designed

- A database of Industrial standard Fins and Gills has been provided so that users can directly select Fin or Gill of thier choice to use in design.

- MKS/SI/FPS units supported

Design SuperHeater for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.

Design SuperHeater for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.- Large database of Waste heat gases and Boiler Exhaust gases is provided.

- All types of Bare tube, Fin tube and Gill tube Superheater can be designed.

- MKS/SI/FPS units supported

Design AirHeater for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.

Design AirHeater for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.- Large database of Waste heat gases and Boiler Exhaust gases is provided.

- All types of Bare tube, Fin tube and Gill tube Airheatercan be designed.

- MKS/SI/FPS units supported

RECENT PROJECTS

The following are the some of the FireCAD designed projects ..

| Project | Description | Project | Description |

|---|---|---|---|

| Baramati Agro | 120 TPH @ 87 kg/cm2 (g), 520°C with 22MW Co-Generation Plant | Ruampol Bio-Power Company Ltd., Thailand | 250 TPH @ 67 kg/cm2 (g), 500°C -2 x 25 MW Co-Generation Plant |

| Samruddhi Sugars Ltd. | 60 TPH @ 67 kg/cm2 (g), 510°C with 7MW Co-Generation Plant | Baramati Agro Ltd. (Unit-2) | 110 TPH @ 87 kg/cm2 (g), 520°C with 22MW Co-Generation Plant |

| Shri Saikrupa Sugars Ltd. | 180 TPH @ 110 kg/cm2 (g), 540°C with 2x20MW Co-Generation Plant | Sovereign Industries Ltd. | 100 TPH @ 110 kg/cm2 (g), 540°C with 18MW Co-Generation Plant |

| Jakraya Sugar Ltd. | 70 TPH @ 67 kg/cm2 (g), 510°C with 12MW Co-Generation Plant | Harsha Sugars Pvt. Ltd. | 140 TPH @ 125 Ata, 545°C with 32MW Co-Generation Plant |

| Shivshakti Sugars Ltd. | 85 TPH @ 87 kg/cm2 (g), 515°C with 15MW Co-Generation Plant | Soubhagya Lakshmi Sugars Ltd. – Unit 2 | 100 TPH @ 87 kg/cm2 (g), 520°C with 18MW Co-Generation Plant |

| Shri Shivsagar Sugar & Agro Products Ltd | 50 TPH @ 72 kg/cm2 (g), 500°C with 3MW Inhouse power plant | Shivshakti Sugars Ltd. Unit 2 | 120 TPH @ 87 kg/cm2 (g), 520°C with 22MW Co-Generation Plant |

| Aryan Sugars Ltd. | 60 TPH @ 72.5 kg/cm2 (g), 510°C with 10MW Co-Generation Plant | Shree Durga Syntex Pvt. Ltd | AFBC- 70 TPH @ 87 kg/cm2 (g), 525°C with 15MW Power Plant |

| Maharashtra Shetkari Sugars Ltd. | 110 TPH @ 110 kg/cm2 (g), 540°C with 20MW Co-Generation Plant | Kibos Sugars & Allied Industries Ltd. | 90 TPH @ 45 kg/cm2 (g), 440°C with 15MW Co-Generation Plant |

| Soubhagya Lakshmi Sugars Ltd. | 100 TPH @ 87 kg/cm2 (g), 515°C with 18MW Co-Generation Plant | Hi-Bond Cement(India) Pvt Ltd | AFBC Boiler- 49 TPH @ 87 kg/cm2 (g), 520°C with 10MW Captive Power Plant |

| Sitaram Maharaj Sakhar Karkhana Ltd | 55 TPH @ 72 kg/cm2 (g), 510°C with 10MW Co-Generation Plant | Galaxy Sugars | 20 TPH @45 kg/cm2 (g), 450°C -2 MW Co-Generation Plant |

| Udgiri Sugar & Power Ltd. | 75 TPH @ 72.5 kg/cm2 (g), 515°C with 14MW Co-Generation Plant | Jyothi Sugars | 15 TPH @ 45 kg/cm2 (g), 425°C -7 MW Co-Generation Plant |

| Agrisilos, Panama | 15 TPH @ 45 kg/cm2 (g), 450°C with 2MW Co-Generation Plant | Eco Farm, Mozambique | 20 TPH @ 45 kg/cm2 (g), 450°C -2.5 MW Co-Generation Plant |