FireCAD : Water Tube Package Boiler Design Software

Water Tube Pkg Boiler Design Software

Water Tube Package Boiler Design Software Features:

- Water tube Package Boiler Design software of FireCAD series, is a simple yet powerful Software for designing Water tube Package Boilers.

- This package helps novice as well as expert design engineers for quick and accurate designs.

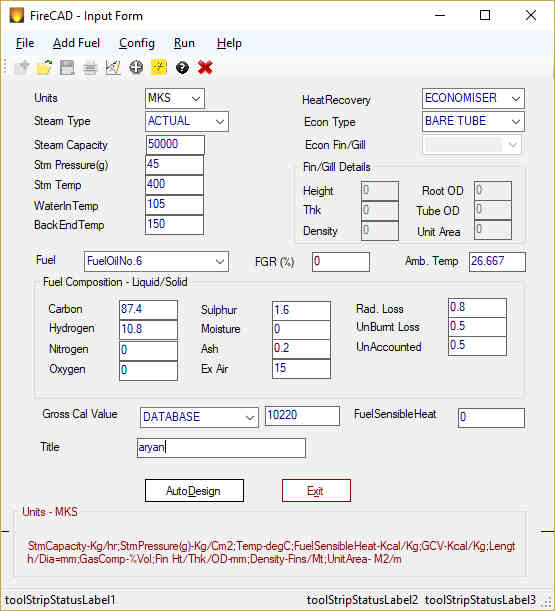

- FireCAD comes with extensive database of Fuels.

- Water Tube Package Boilers upto 150,000 Kg/hr and 170 Kg/cm2 pressure can designed

- Both Oil Boilers and Gas Boilers can be designed.

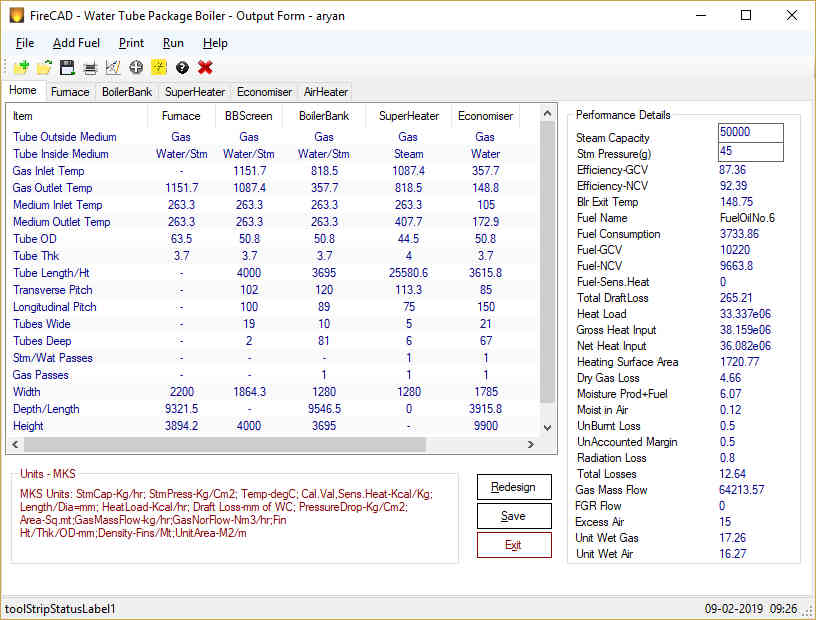

- Complete system with SuperHeater, Economizer and AirHeater can be designed.

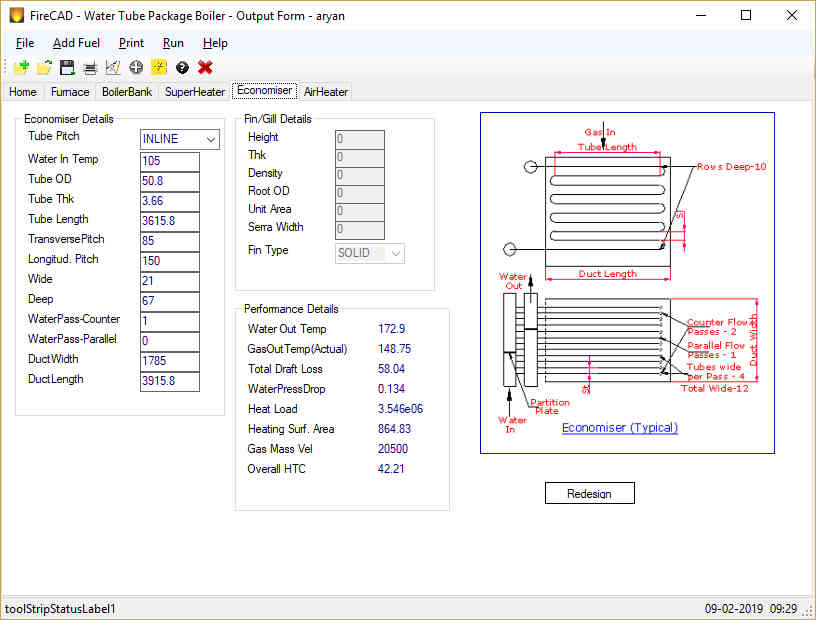

- Option to include Economizer with Bare/Fin/Gill tubes.

- Flue Gas Recirculation (FGR) option is available.

General Features of FireCAD software:

- Optimum design with AutoDesign feature

- Extensive Fuel database.

- Custom Fuels can be added to database

- Extensive help giving Design methodologies, Design tips and Good Engineering practices

- Detailed report of the final design with Print option

- MKS/SI/FPS units supported

Brief Description of Water tube package boilers

About:

These are shop assembled and bi-drum boilers. Fuel is either oil or gas. Fuel is fired in the furnace with the help of burners.

Configuration

The boiler consists of furnace, bi-drum boiler bank and economizer and sometimes an air heater. There are several types of water tube package boilers based on shape of the boiler like , ‘D’ type, ‘O’ type , ‘A’ type etc. ‘D’ type boilers are most widely used.

Boiler Parts:

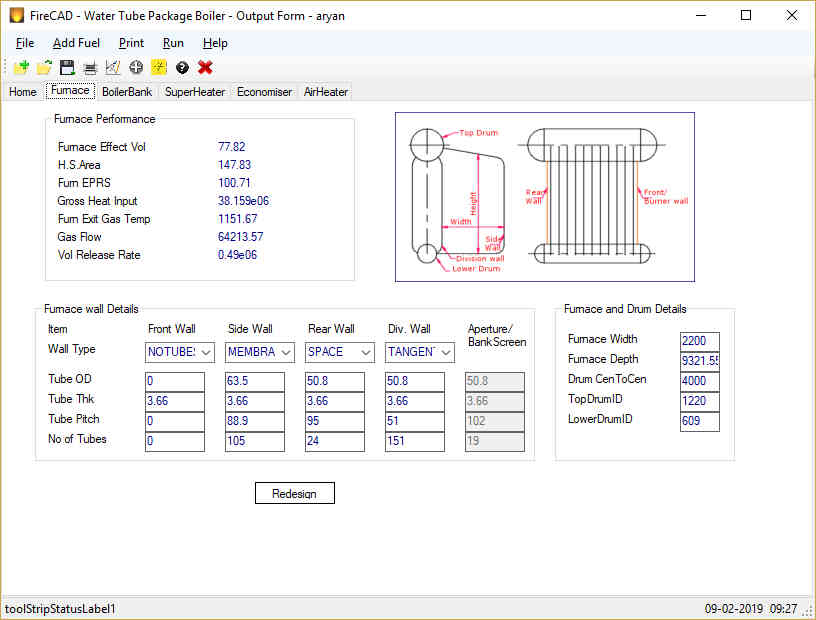

Furnace

Furnace is usually membrane walled and gas tight. Most of the heat transfer occurs in the furnace in the form of direct radiation. ‘D’ type furnace is widely used compared to other configurations. Most of these boilers operate under positive pressure on gas side as there are provided only with FD fan and no ID fan. So leak proof casing is very much required to arrest gas leakage into boiler room.

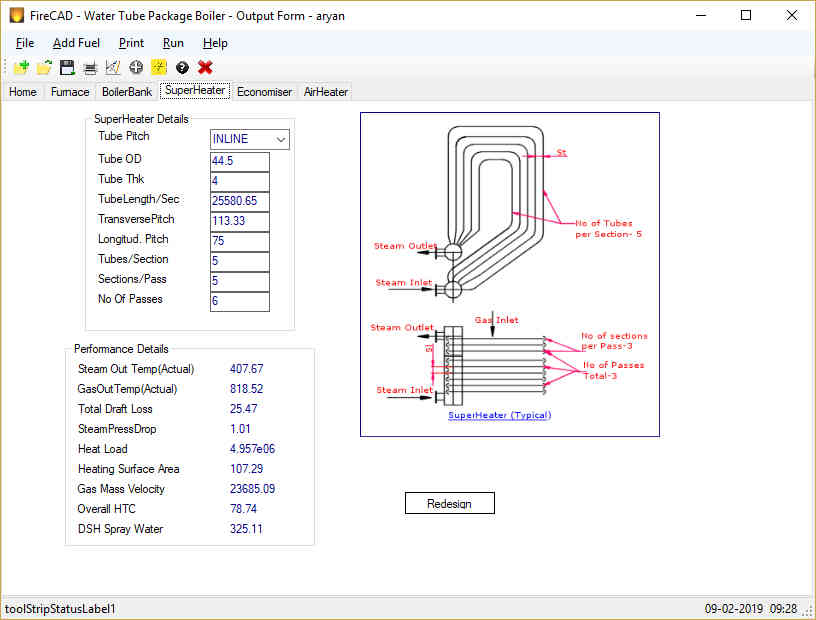

Superheater

There are several types of superheaters employed in water tube package boilers. Inverted ‘U’ is most widely used. There are other types like vertical ‘S’ type drainable. Superheater is usually embedded in the boiler bank. When superheat temperature is high, part of the superheater section is directly place in the furnace to increase direct radiation and reduce size.

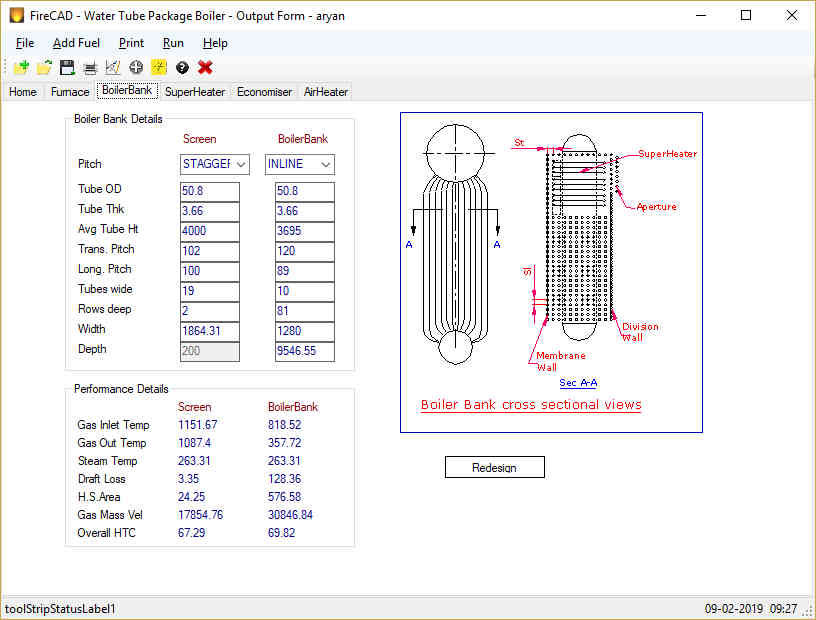

Boiler Bank

Boiler bank connects both the drums. Natural circulation occurs with out the aid of any external downcomers. First 20-30% rows act as risers and the rest act as downcomers. Membrane division wall separates the boiler bank and the furnace. Drum coil heaters are provided in the lower drum to preheat the feed water before sending it to Economizer.

Economizer

Economizer is used downstream of Boiler bank to preheat the feed water absorbing heat from hot exhaust gases. Economizers are always water tube type. Bare tubes in Economisers are widely used in Industrial boilers and in some applications like Heat recovery boilers in Sulfuric acid plants, Gilled tubes are employed. Finned tubes are popular in HRSG applications. Economizers are retrofitted to many old boilers to increase the fuel efficiency of the boiler. Feed water can be heated up to a level about 20 – 30 C below saturation temperature of the boiler. Economizers need hot water input to reduce condensation of corrosive gases like SO2 on tubes. Depending up on the sulfur content in the fuel, water inlet temperature of 80 C up to 150 C is required for economizers.

Boiler Parts

Boiler parts include boiler sections like furnace,superheater,boiler bank,economizer,airheater, steam and water drums. Fuel firing equipment like oil burner,gas burner,ring main system, oil tanks and oil preheating equipment.