FireCAD : Water Tube Package Boiler Design Software

Water Tube Pkg Boiler Design Software

Water Tube Package Boiler Design Software – FireCAD

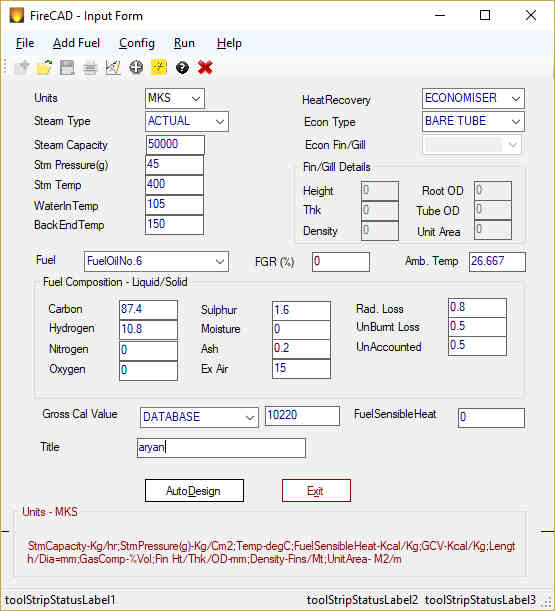

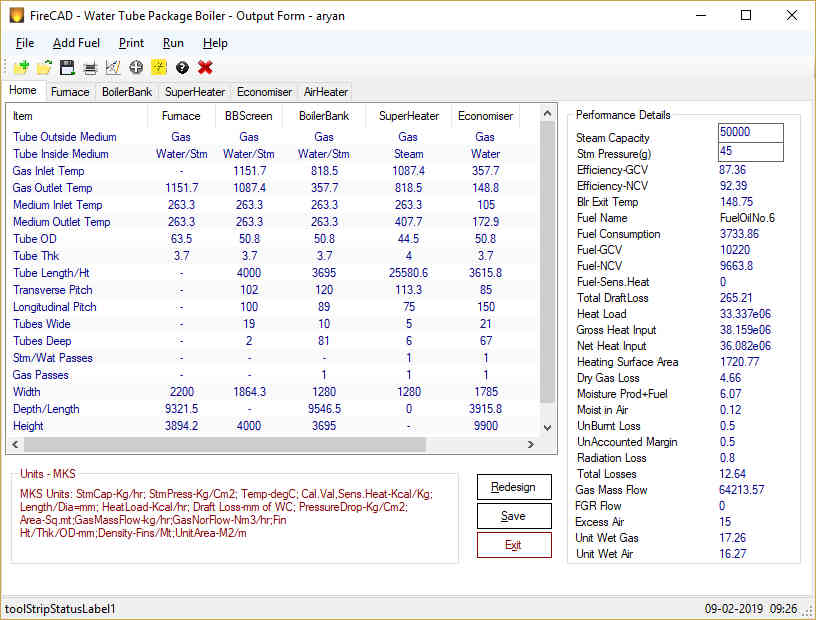

FireCAD is a powerful yet user-friendly software solution designed for engineers of all levels who need to quickly and accurately design water tube package boilers.

Capabilities:

- Design a wide range of boilers: Create designs for oil-fired, gas-fired, and combination boilers with capacities up to 150,000 kg/hr and pressures up to 170 kg/cm².

- Comprehensive system design: Include Superheaters, Economizers with Bare/Fin/Gill tubes, and AirHeaters in your designs.

- Optimize for efficiency: Utilize Flue Gas Recirculation (FGR) options to maximize boiler performance.

- Extensive fuel database: Access a vast library of fuel data, with the ability to add custom fuels.

Features:

- AutoDesign: Achieve optimized designs with the automated design feature.

- Expert guidance: Benefit from built-in help resources that provide design methodologies, tips, and best engineering practices.

- Detailed reporting: Generate comprehensive design reports with printing options.

- Flexible units: Work in MKS, SI, or FPS units.

FireCAD empowers you to:

- Save time: Streamline your design process with intuitive tools and automated features.

- Reduce errors: Improve accuracy with built-in checks and comprehensive calculations.

- Optimize performance: Design efficient and reliable boilers that meet your specific requirements.

Water Tube Package Boilers: A Compact and Efficient Solution

Water tube package boilers are factory-assembled, bi-drum boilers designed for efficient steam generation using oil or gas fuel. These compact units are known for their rapid start-up times and ease of installation, making them ideal for a variety of industrial applications.

Key Components and Configurations:

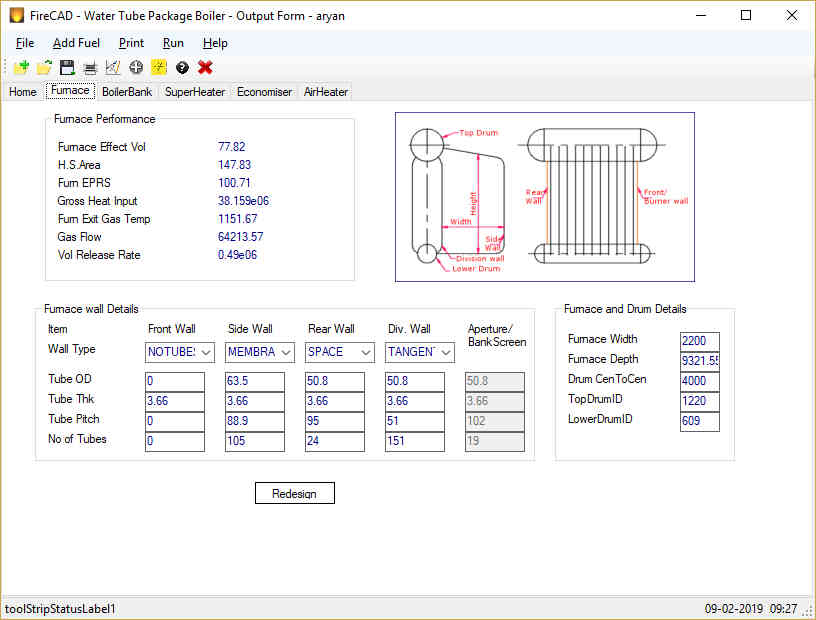

- Furnace: Typically a membrane-walled, gas-tight structure where fuel combustion occurs. The “D” type furnace is a popular configuration known for its efficient heat transfer through direct radiation.

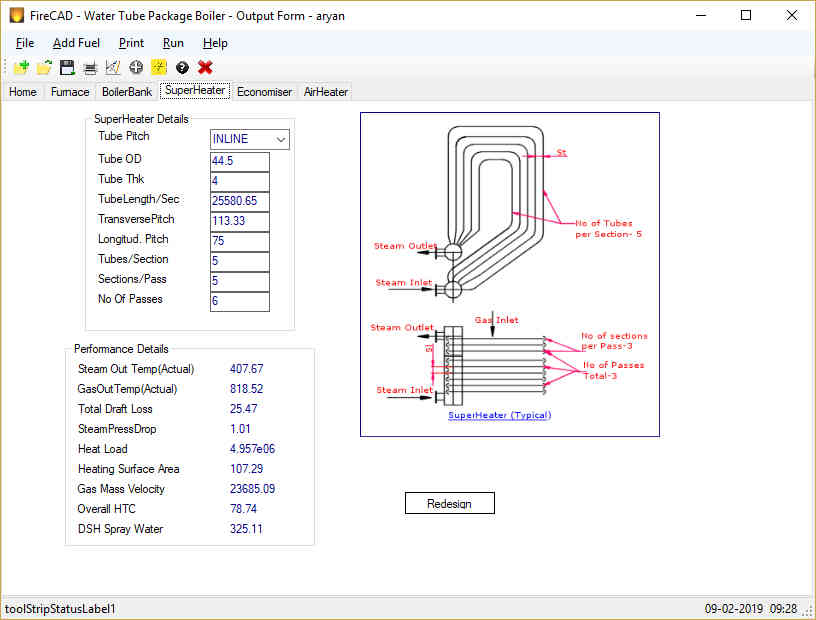

- Superheater: Increases steam temperature for improved efficiency. Inverted “U” and vertical “S” type designs are common, often integrated within the boiler bank or positioned in the furnace for higher temperature applications.

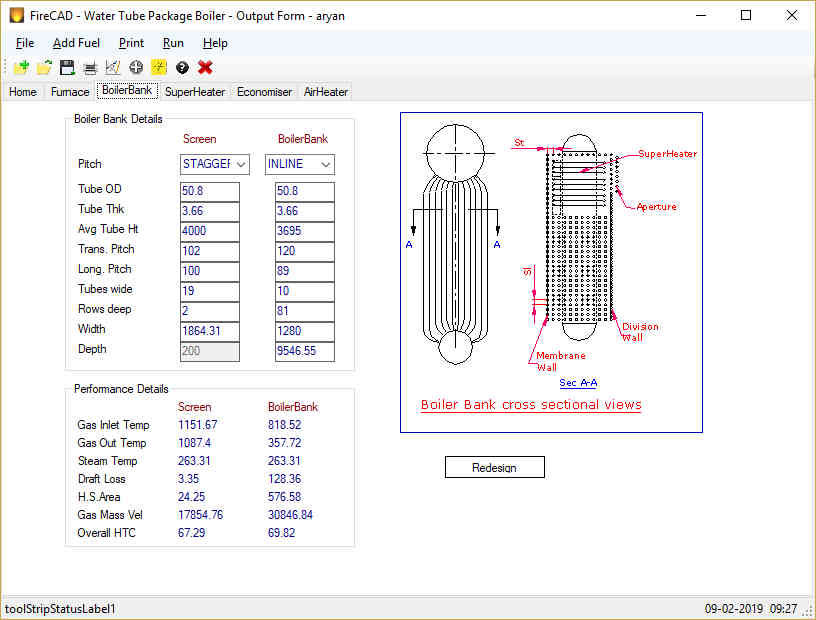

- Boiler Bank: Connects the steam and water drums, facilitating natural circulation. The membrane wall separates the boiler bank from the furnace, ensuring efficient heat transfer.

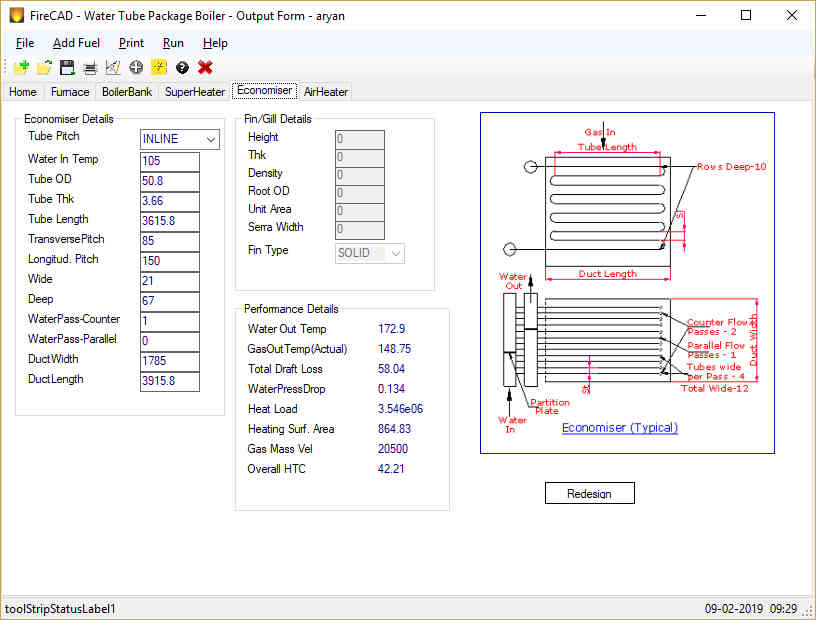

- Economizer: A heat recovery unit that preheats feed water using exhaust gases, improving overall boiler efficiency. Bare, finned, and gilled tube economizers are available to suit different fuel types and operating conditions.

- Air Heater (Optional): Further enhances efficiency by preheating combustion air, reducing fuel consumption.

Types of Water Tube Package Boilers:

While various configurations exist, “D” type boilers are the most widely used due to their efficient design and compact footprint. Other types include “O” type and “A” type, each offering unique advantages for specific applications.

Advantages of Water Tube Package Boilers:

- Compact Design: Factory assembly minimizes on-site installation time and costs.

- Rapid Start-Up: Quickly generate steam to meet fluctuating demands.

- High Efficiency: Optimized heat transfer and optional components like economizers and air heaters maximize fuel utilization.

- Versatility: Suitable for a wide range of fuels, including oil, gas, and combinations.

- Easy Maintenance: Accessible components simplify inspection and maintenance procedures.