Welcome

FireCAD Technologies has carved a niche for itself with expertise in design and engineering of cogeneration plants & power plants and software development for industrial steam boilers. All our Boiler Design software is made available as Web applications. FireCAD’s emphasis is on developing user friendly Software. Our satisfied clientele over the globe using FireCAD Software has encouraged a greater commitment.

FireCAD software is being used by Steam Boiler manufacturers and Engineering consultants across the globe from over 30 countries. Design software for Grate Fired Boilers, Water Tube Package Boilers, Fire Tube Boilers both fired and waste heat type (Steam Boiler and Hot Water Boiler), Combi boilers, Economizers, Air heaters and Superheaters is available. We offer design consultancy for various Industrial Boilers like Oil fired Boiler, Gas Boiler, Wood boiler, hot water boiler and Combi boiler.

FireCAD Software

- Grate Fired Boiler Design Software – 3 tph to 250 tph of steam

- Fire Tube Boiler Design Software – 200 kg/hr to 50 tph

- Water Tube Pkg Boiler software – 3 tph to 150 tph

- Econimizer design software – up to 1000 tph

- Superheater design software

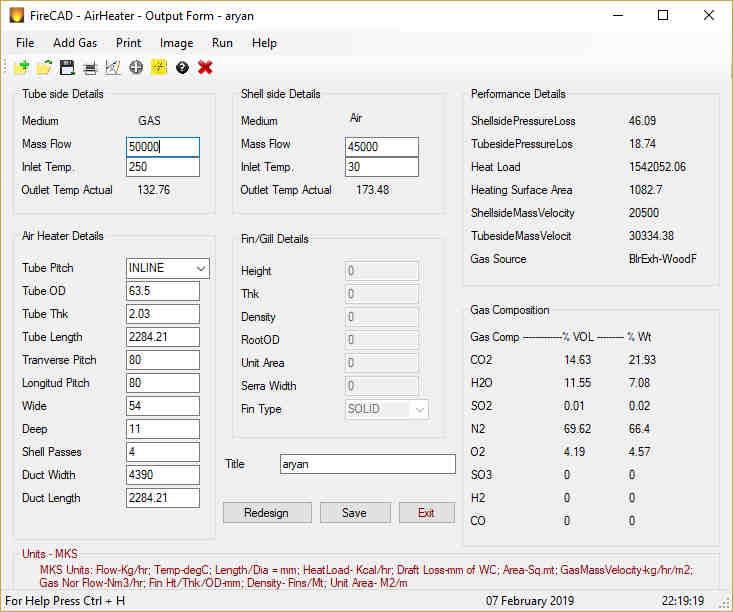

- Airheater design software

Clients:

Saskatoon Boiler Manufacturing co Ltd., Canada

Alpha Omega ltd.,Indonesia

Cannon Boiler Works Inc,USA

The McBurney Corp,USA

Garma Gostar Co.,Iran

Vea AB ,Sweden

Zenith Thermal Equipment Pvt.Ltd.,India

Descon Engineering Ltd.,Pakistan

Soils Inc,USA

Proodos Industrial Boilers,Greece

Viitos-Metalli,Finland

McKillup Engineering, Inc,USA

MMI Boiler Management Pte Ltd.,Singapore

Idaho National Engineering & Environmental Laboratory,USA

Simon India Ltd,India

Hurst Boiler & Welding Co.,Inc,USA

ATS Express, LLC,USA

Del-Tech Industries Inc.,Canada

Recovery Heat Engineering S.A. de C.V,Mexico

PT. Dinamika Energitama Nusantara,Indonesia

Eco-wat A/S,Bulgaria

Thermodesign Inc,Canada

Steam Master Equipamentos Térmicos Ltda,Brazil

Snow Removal Systems, Inc,USA

Lointek, S.L,SPAIN

PT Mitra Adyaniaga,INDONESIA

Grate Fired Boiler Design Software

- Solid fuel fired Steam Generators up to 250,000 Kg/hr and 550 degC can be designed.

- Fuels : Coal, Lignite, bagasse, Rice husk, wood ,other Bio-mass boilers

- Grates : Dumping Grate, Travelling Grate, Stationery and Water Cooled Grates

- Furnace : Membrane tubes, Tangent Tubes, Space Tubes or Refractory wall

- SuperHeater : Single Stage and Two stage. Counter and Parallel flow type with or without protective screen.

- Boiler Bank: Water Tube or Fire Tube boiler Bank. Combination Boilers or Combi boilers with water tube furnace and Fire Tube Boiler bank.

- Water Tube boiler Bank : Cross Flow or Long Flow type.

- Fire Tube Boiler : Single Pass or Two Pass.

- Economizer: Single pass or Multi pass with Bare/Fin/Gill tubes.

- Air Heater: Single or Multi Pass.

- Headers, Downcomers , Feeders and Risers sizing

- Units : SI/MKS/FPS available

Fire Tube Boiler Software

- Useful for designing Fire Tube Package Boilers and Waste heat boilers of any range and pressure

- Oil fired boilers,gas fired boilers and coal other solid fuel fired boilers can be designed

- Novice as well as expert design engineers for quick and accurate designs.

- Extensive Fuel and Waste gases database.

- Wet back or Dry back and 2,3,4 pass Boilers can be designed.

- Waste heat boilers(Fire Tube) for Chemical/DG set/Process/Metallurgical/Power plants can be designed.

- Fired/Unfired Hot Water Generators can be designed.

- Option to include Economiser with Bare/Fin/Gill tubes.

- MKS/SI/FPS units supported

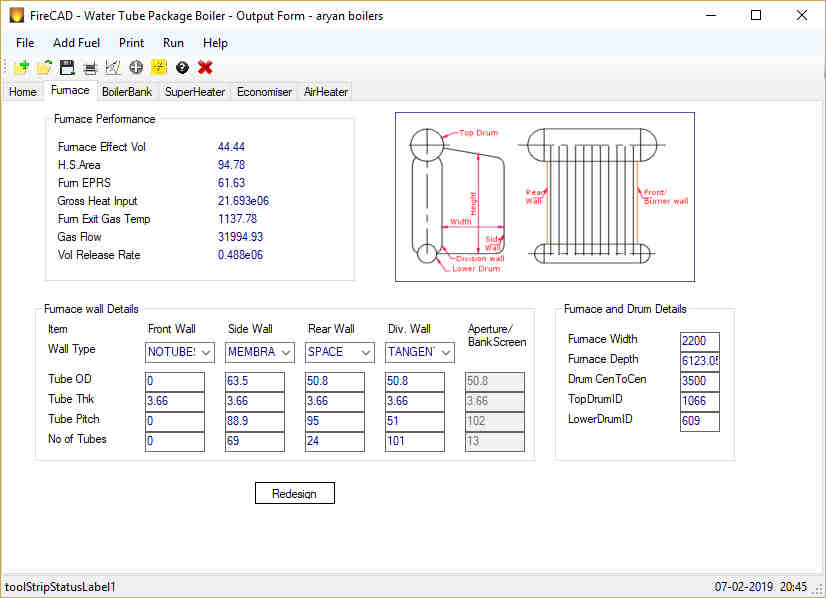

Water Tube Package Boiler

- Water Tube Package Boilers up to 150,000 Kg/hr and 170 Kg/cm2 pressure can designed

- Oil as well as Gas fired Boilers can be designed.

- Novice as well as expert design engineers for quick and accurate designs.

- Extensive Fuel database.

- D-type package boilers

- Option to include Economizer and Air-heater with Bare/Fin/Gill tubes.

- MKS/SI/FPS units supported

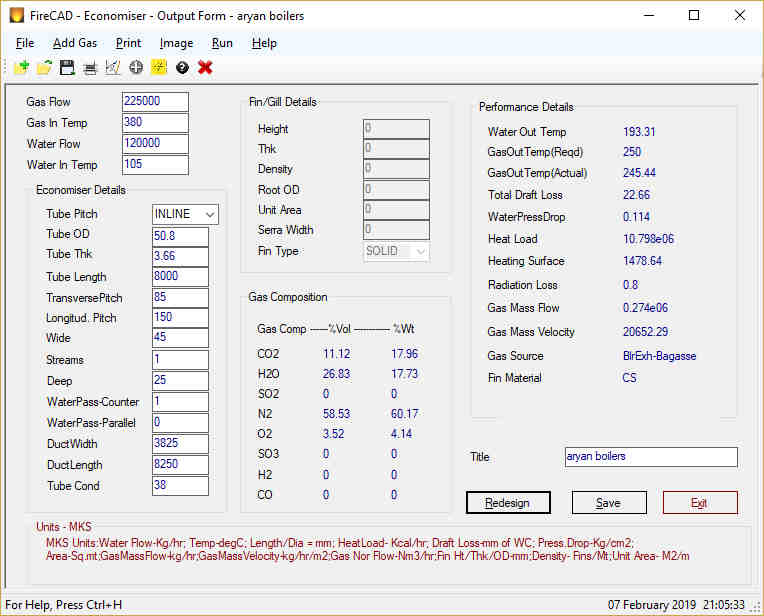

Economizer Design Software

- Design a wide variety of Economisers for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.

- Large database of Waste heat gases and Boiler Exhaust gases is provided.

- All types of Bare tube, Fin tube and Gill tube Economisers can be designed.

- Bare tube, Fin tube and Gill tube Economisers can be designed

- A database of Industrial standard Fins and Gills has been provided so that users can directly select Fin or Gill of thier choice to use in design.

- MKS/SI/FPS units supported

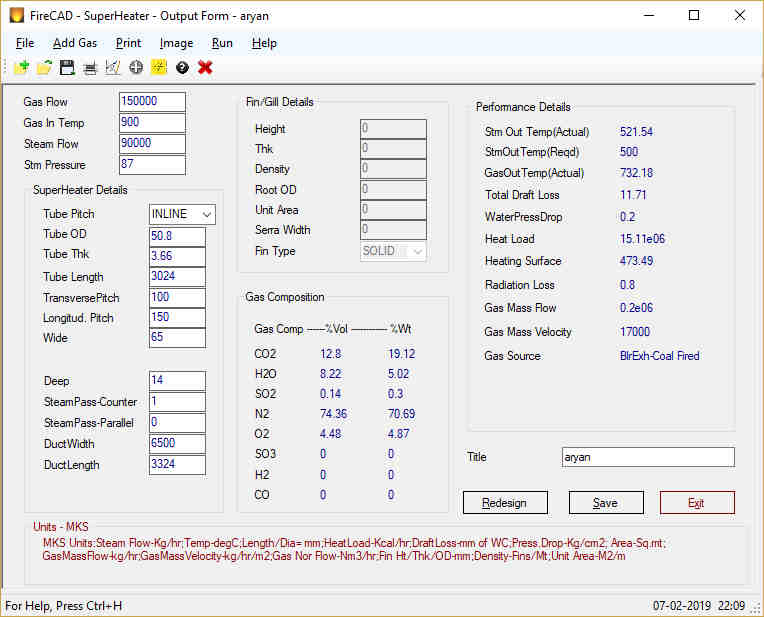

Superheater

- Design SuperHeater for Fired Boilers, Waste Heat Boilers, HRSGs and for other hot gas sources of Chemical plants.

- Large database of Waste heat gases and Boiler Exhaust gases is provided.

- All types of Bare tube, Fin tube and Gill tube Superheater can be designed.

- MKS/SI/FPS units supported

RECENT

PROJECTS

The following are the some of the FireCAD designed projects ..

| Project | Description | Project | Description |

|---|---|---|---|

| Baramati Agro | 120 TPH @ 87 kg/cm2 (g), 520°C with 22MW Co-Generation Plant | Ruampol Bio-Power Company Ltd., Thailand | 250 TPH @ 67 kg/cm2 (g), 500°C -2 x 25 MW Co-Generation Plant |

| Samruddhi Sugars Ltd. | 60 TPH @ 67 kg/cm2 (g), 510°C

with 7MW Co-Generation Plant |

Baramati Agro Ltd. (Unit-2) | 110 TPH @ 87 kg/cm2 (g), 520°C

with 22MW Co-Generation Plant |

| Shri Saikrupa Sugars Ltd. | 180 TPH @ 110 kg/cm2 (g), 540°C

with 2x20MW Co-Generation Plant |

Sovereign Industries Ltd. | 100 TPH @ 110 kg/cm2 (g), 540°C

with 18MW Co-Generation Plant |

| Jakraya Sugar Ltd. | 70 TPH @ 67 kg/cm2 (g), 510°C

with 12MW Co-Generation Plant |

Harsha Sugars Pvt. Ltd. | 140 TPH @ 125 Ata, 545°C

with 32MW Co-Generation Plant |

| Shivshakti Sugars Ltd. | 85 TPH @ 87 kg/cm2 (g), 515°C

with 15MW Co-Generation Plant |

Soubhagya Lakshmi Sugars Ltd. – Unit 2 | 100 TPH @ 87 kg/cm2 (g), 520°C

with 18MW Co-Generation Plant |

| Shri Shivsagar Sugar & Agro Products Ltd | 50 TPH @ 72 kg/cm2 (g), 500°C

with 3MW Inhouse power plant |

Shivshakti Sugars Ltd. Unit 2 | 120 TPH @ 87 kg/cm2 (g), 520°C

with 22MW Co-Generation Plant |

| Aryan Sugars Ltd. | 60 TPH @ 72.5 kg/cm2 (g), 510°C

with 10MW Co-Generation Plant |

Shree Durga Syntex Pvt. Ltd | AFBC- 70 TPH @ 87 kg/cm2 (g), 525°C with 15MW Power Plant |

| Maharashtra Shetkari Sugars Ltd. | 110 TPH @ 110 kg/cm2 (g), 540°C

with 20MW Co-Generation Plant |

Kibos Sugars & Allied Industries Ltd. | 90 TPH @ 45 kg/cm2 (g), 440°C

with 15MW Co-Generation Plant |

| Soubhagya Lakshmi Sugars Ltd. | 100 TPH @ 87 kg/cm2 (g), 515°C

with 18MW Co-Generation Plant |

Hi-Bond Cement(India) Pvt Ltd | AFBC Boiler- 49 TPH @ 87 kg/cm2 (g), 520°C with 10MW Captive Power Plant |

| Sitaram Maharaj Sakhar Karkhana Ltd | 55 TPH @ 72 kg/cm2 (g), 510°C

with 10MW Co-Generation Plant |

Galaxy Sugars | 20 TPH @45 kg/cm2 (g), 450°C -2 MW Co-Generation Plant |

| Udgiri Sugar & Power Ltd. | 75 TPH @ 72.5 kg/cm2 (g), 515°C

with 14MW Co-Generation Plant |

Jyothi Sugars | 15 TPH @ 45 kg/cm2 (g), 425°C -7 MW Co-Generation Plant |

| Agrisilos, Panama | 15 TPH @ 45 kg/cm2 (g), 450°C

with 2MW Co-Generation Plant |

Eco Farm, Mozambique | 20 TPH @ 45 kg/cm2 (g), 450°C -2.5 MW Co-Generation Plant |